Story about Iron: Universe, Civilization & Iron, and Environment

Story about Iron: Universe, Civilization & Iron, and Environment

Instructer: Dr. SUNAHARA Kohei

Senior Manager, Head of Research Plant

Experimental Blast Furnace Project Division

R&D Laboratories Process Research Laboratories

Nippon Steel Corporation

Date: Friday, May 21, 2021

Venue: Minato City Life-long Learning Center

MUA started a new series of salon to foster a worldwide viewpoint, where we invite speakers who work at the forefront of different fields. As the first speaker, we invited Dr. Sunahara and asked him to talk about iron which is the core of the steel industry.

Major topics in Dr. Sunahara’s presentation included the following:

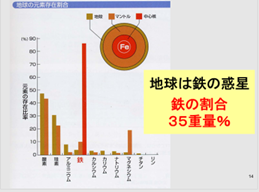

1.Why is the earth a planet of iron?

・The earth was born 4.5 billion years ago, with iron accounting for 30% of its constituents.

・Four thousand years ago, the Hittite people started to use iron tools, kicking off the history of civilization and iron.

・During the 100-year-long Anglo-French War which started in the 14th century, devastation of forestry took place because of the need to burn tons of wooden coal to produce iron weapons and warships. This marked a harbinger of global environmental challenge.

2.Interrelation among iron, forests and fire: This topic enlightened us on the process of how mankind made accumulated efforts to enhance the availability of iron up to a civilization level.

3.Contemporary interrelation between steel production and efforts to secure a clean environment. Government and corporate initiatives to protect natural environment.

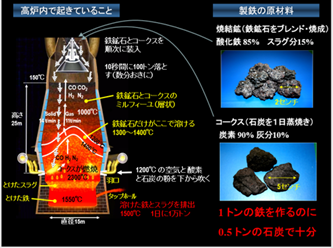

Dr. Sunahara elaborated on the long history of the universe, the solar system, and the birth of the earth and the sea (from 13.8 billion years ago up to 4.4 ~ 4.6 billion years ago). Then he touched on the history of human civilization, referring to the major elements – iron, forests and fire. During the Bronze Age (6,000 years ago), mankind had to cut down over 2,000 pine trees, to be converted into about 100 ton of wood coal, each time they needed to produce one ton of copper. It was followed by the discovery of iron by the Hittite, as mentioned above, during the copper smelting process. To produce one ton of iron, only ten ton or less of wooden coal was needed.

It was during the 6th century when iron production travelled to Japan. Dr. Sunahara highlighted the advantage Japan had in iron production, including ubiquitous availability of iron ores and iron sand as well as rich and sustainable forestry. Japanese cutlery is renowned for excellent cutting quality. For example, Japan offers an extensive variety of carving knives which are well tuned for cutting meet, fish or vegetables.

During the Industrial Revolution period, from the 17th century to the 19th century, coal was discovered and treasured as “Black Diamond.” The use of fossil fuel reduced the devastation of forests and helped recover greenery. Japan was blessed with much rain and rich forestry which enabled the production of high-quality yet low-quantity iron products such as Japanese swords, utilizing the traditional “Tatara” foot bellows technique. Today, however, the mass production of steel in Japan cannot be sustained without the import of coal and iron ores.

Major supply of iron ores comes from Brazil and Australia. Approximately 0.5 ton of coal is consumed to produce one ton of steel.

During the 1960’s, the excessive use of coal and petroleum, both fossil fuel, has caused the enormous exhaustion of carbon dioxide, resulting in the global warming. In Japan, the iron & steel industry accounts for about half of carbon dioxide exhaustion. Therefore, it is an impending challenge for all Japan to work out ways to reduce carbon dioxide exhaustion. As an alternative energy, hydrogen has emerged as a promising source and is attracting an increased attention from the car industry, including Toyota in Japan, for example.

Today the technological trend featuring “Carbon Free” is often labelled as the Fourth Revolution, following the Agricultural Revolution, the Industrial Revolution, and the Information Revolution. In the Japanese iron & steel industry, a national project called “COURSE 50” started in 2008, addressing a world’s highest energy efficiency during the manufacturing process. This project also pursues the reduction of carbon dioxide exhaustion, to establish a viable way to combat global warming.

(Written by KOBAYASHI T., Standing Director, the Membership Committee, and translated by TANAHASHI S., the PR & Internet Committee)